ICCK Journal of Applied Mathematics

ISSN: 3068-5656 (Online)

Email: [email protected]

The consideration of magnetohydrodynamic (MHD) in moving fluids grabs the attention of researchers due to its attractive and significant usages in physiology and technical industry. Externally applied magnetic field play an important role in drug delivery to targeted points. Flow due to periodic waves propagations becomes more significant in bio medical industry when magnetic field is applied. It is important during bleeding preventions, hyperthermia, ulcer, inflammation etc. treatment. The above mentioned usages of MHD, researchers consider it in peristaltic motion with various aspects. Peristaltically driven flow in the presence of magnetic field and heat transfer of tiny particles is managed by Bhatti et al. [1]. Peristaltic motion of different shape sized nanoparticle with MHD is introduced by Khan et al. [2]. Nanofluid peristaltic movement through an asymmetric channel with entropy generation and MHD is discussed by Ali et al. [3]. Magnetic field is applied in the cilia motion through curved propagating channel with heat exchange is presented by Sadaf and Nadeem [4]. Ali et al. [5] incorporates the Hartmann boundary layer existence in viscoelastic fluid peristaltic movement.

Various clinical and engineering procedures operate via peristaltic mechanisms. It is an inherent property of various physiological organs due to sinusoidal movements of waves e.g. intestine, ureter, lungs, digestive tract, fallopian tube, bile ducts, arteries. Earthworms loco movement is also obeys the peristaltic mechanism. Ceramics and sanitary liquid transport are the industrial applications of peristalsis. Various bio-medical gadgets such as dialysis, heart-lung, blood pressure, nebulizer machines and different clinical injections, coronary bypass, hose pumps are working through mechanism of peristalsis. In light of these applications Latham [6] and Shapiro et al. [7] model and investigates the peristalsis firstly for large wavelength numerically and theoretically. Further Yin and Fung [8, 9] discuss the peristaltic movement through cylindrical ducts. Subsequent studies have advanced peristaltic flow analysis through diverse approaches: Hussain et al. [10] developed a shooting technique for curved radiative flows, while Ranjit et al. [11] quantified entropy generation in electroosmotic microchannels. Numerical innovations include Priam's [12] Casson fluid simulations and Mallick's [13] electromagnetic Eyring-Powell model, complemented by Yasmeen's [14] quantitative/qualitative Jeffrey fluid analysis and Rafiq's [15] Hall/ion-slip nanofluid applications.

The mechanism of heat transfer from lower to higher temperature places is most important and has crucial utilizations in the procedure of haemodialysis and oxygenation. Heat conduction in biological tissues, environmental heat exchangers, cooling system of industrial and mechanical devices, hyperthermia etc. are few more significant examples of heat transfer. Several researchers analyse the characteristics of heat transfer in various physiological liquids transportation. Peristaltic motion with heat transfer was initially investigated by Vajravelu et al. [16] through perpendicular porous tube. Riaz et al. [17] examined fluids irregular motion which is supportive and supply of liquids in a uniform pattern to control temperature fluctuation in the flow field. The complaint properties at wall and transfer of heat under large wavelength and low Reynolds number approximations was studied by Hayat et al. [18]. Another important impulsive resistive situation based on the production of heat transfer when electric current passes through electrically conductive liquid is Joule heating. Hayat et al. [18] examine the transport of liquid through peristaltic principle in a curved configuration with Joule heating, thermal radiation and dissipation features. Magneto Carneau liquid peristaltic flow through curved channel is theoretically examined by Hayat et al. [20]. Shamsuddin et al. [21] incorporates the Joule heating aspects in power-law liquid with slip constraints. Recent advances in peristaltic flows with Joule heating have significantly expanded the theoretical and computational frontiers: Hayat et al. [22] established fundamental slip condition frameworks for nanofluids, while Gireesha et al. [23] quantified entropy generation in inclined microchannels. Geometric innovations emerged through Sucharitha et al.'s [24] flexible wall analyses and Abbasi et al.'s [25] tapered channel radiation models, complemented by Usman et al. [26] and Kodi et al.'s [27] advanced numerical treatments of Riga surfaces and 3D rotational flows. Fractional calculus approaches were advanced by Rubbab et al. [28] using Caputo-Fabrizio operators, synergizing with Rehman et al.'s [29] Jeffery fluid benchmarks and Li et al.'s [30] breakthroughs in activation energy coupling for micropolar nanofluids.

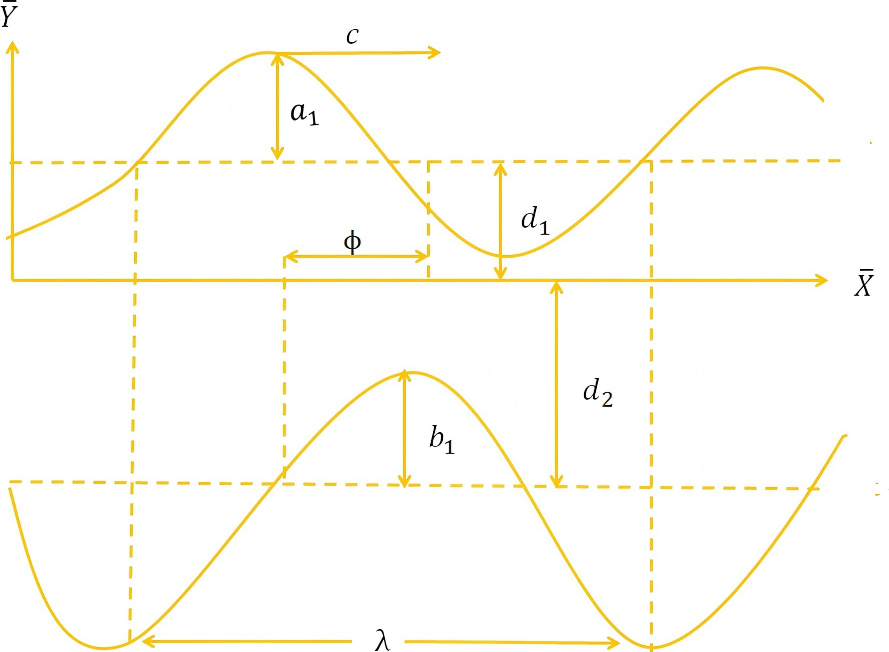

Here peristalsis on an incompressible and highly electrically conducting Jeffery material through asymmetric configuration. Fluid is flowing because of asymmetric propagation of waves with speed (see Figure 1). Channel is of width . Rectangular coordinates and are respectively taken along and normal to the asymmetric walls. Magnetic field of large intensity is executed normal to the flow. Permeability effects are encountered through modified Darcy's principle and energy equation comprises the viscous dissipation and Joule heating features.

Asymmetric channel walls mathematically are expressed as given below:

Equations which govern the Jeffery fluid flow in compact form are:

where and denote the velocity field, the material time derivative, the pressure, the fluid density, and the magnetic field strength, current density, velocity gradient, the permeability, and the specific heat capacity respectively. The extra stress tensor for Jeffrey fluid is given as follows:

Eqs. (3) - (5) in expanded form yields:

Conditions at boundaries are taken in the form at

Stress components are

To transform the system (7-15), the following relation between fixed and moving frames are utilized.

Variables in dimensionless are defined as:

Relation between dimensionless velocity component and stream function is

Using fixed to wave frame transformations (16), dimensionless variables (17) and velocities in terms of stream suction (18) Eqs. (7) satisfied identically and the other expressions takes the following form:

Dimensionless numbers arises in Eqs. (19-24) are defined as

Boundary conditions becomes

Eqs. (19–24) yields after employing dominating large viscous forces (i.e., Re 1) and wavelength (i.e., 1) conditions:

where is given in Eq. (31). After using the cross differentiation technique, Eqs. (28 and 29) yields.

In this chapter we use the similar methodology (i.e asymptotic analysis) to evaluate Eq. (32) with respective boundary conditions. Using this solution Eq. (30) with respective boundary condition is solved numerically through ND Solve command in Mathematica 9.0.

For large approximate solution is obtained away and adjacent to the channel boundaries and then match it with solution at the edges of boundaries. After that a uniform composite solution is obtained.

Express Eq.(32) in terms of Eq.(33) to evaluate asymptotic solution for very large .

where and where . Then the leading order equation of Eq. (32) and its solution is:

Similarly, the first order equation and its solution is:

Combining Eqs. (34 and 36), the asymptotic solution up to order is:

where , , and can be calculated through comparing the higher order term of inner and outer solutions. Here we evaluate two inner solutions to attain a valid and uniform solution at two boundaries because outer solution is not valid at .

(i) For inner solution at , Eq. (32), the solution near to the boundary at , the stretched variable is in the form yields:

Taking in view of least degeneracy condition to balance the solution of Eq. (39) because viscosity effects must be present in inner solution.

in which Eq. (40), . The condition at boundary becomes:

The two term solution of Eq.(40) is assumed as

where Zeroth order system and its solution is of the form:

The two term inner solution at is obtained by putting Eqs. (45 and 48) in , we get:

(ii) In similar manner the two term inner solution is found at by using in Eq. (39).

The values of all constants appearing in Eqs.(49 and 50) is found by comparing inner and outer solutions at both walls.

To employ higher order mode of matching procedure use an intermediate variable given in Eq. (50) at in the intermediate location . Two terms inner and outer solution in the form of variable at by neglecting the terms higher than and greater after converting the outer and inner solutions into intermediate parameter at lower plate yields:

implies:

Similarly at upper plate , matching of outer and inner solutions is:

Eq.(53) and Eq.(54) are evaluated simultaneously to obtain the unknown constants:

The composite solution can be expressed as:

Now, using Eq.(49), Eq. (50) and Eqs. (51,52) into Eq. (56), the composite solution is finally given by:

The composite solution presented in Eq. (57) is completely valid for all independent variable values which fulfills the accounted boundary conditions.

The goal of this section is to study the graphical behaviour of velocity and temperature profiles against Darcy number , Hartmann number (), Jeffery fluid parameters and Brinkmann number .

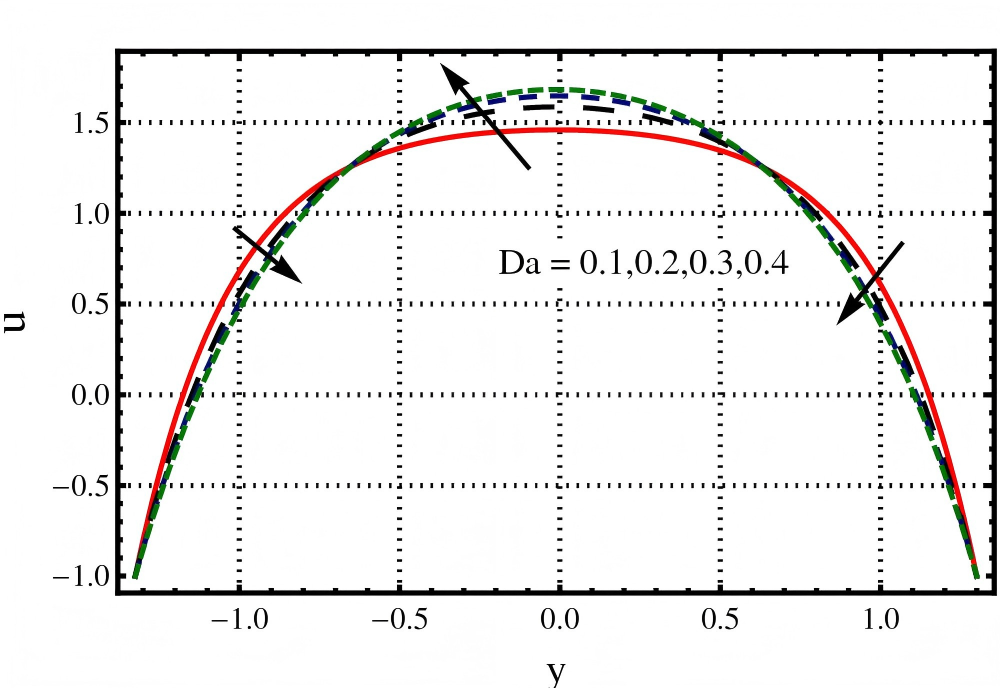

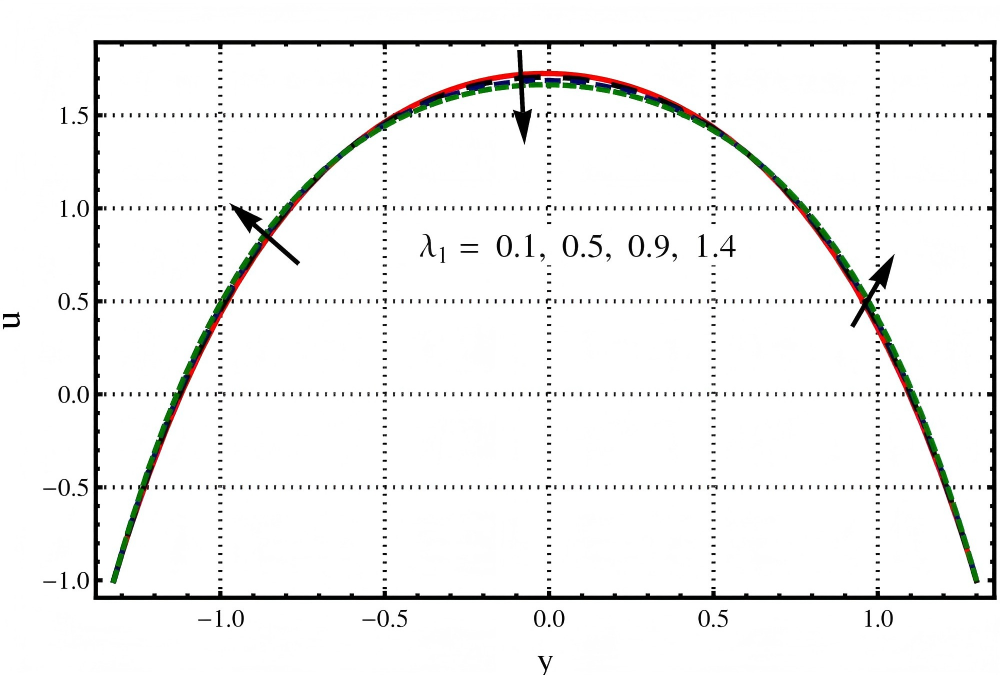

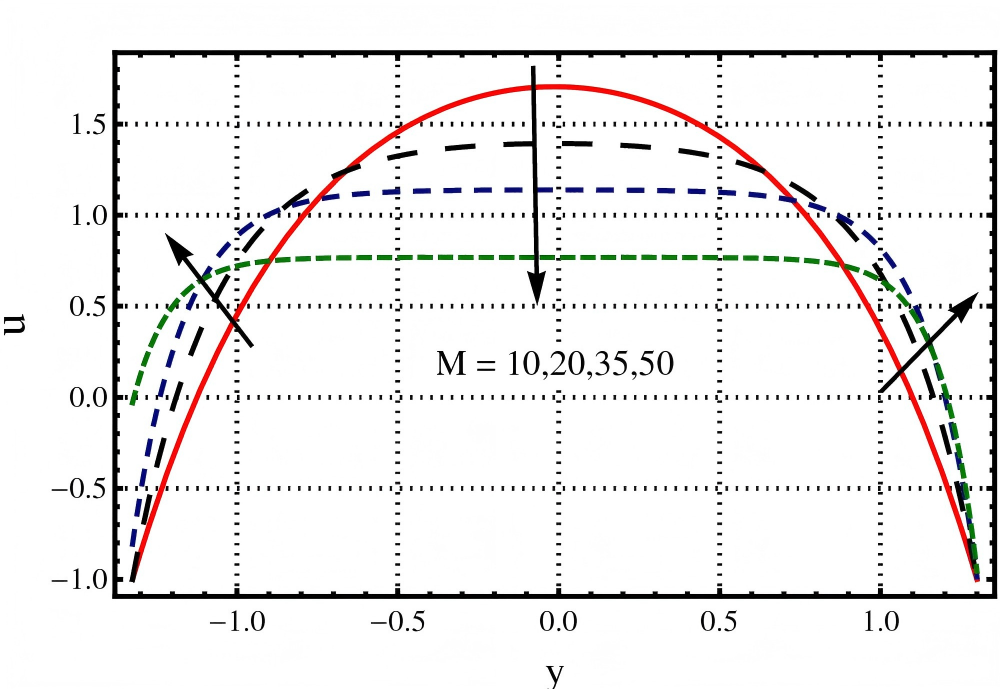

The impact of , and on velocity profile are captured in Figures 2, 3 and 4. The velocity of flowing fluid increases with an increase in Darcy number () as graphically presented in Figure 2. When studying peristaltic flow through veins and arteries, the porosity of walls must be considered. Because an increase in porosity causes a reduction in drag force gives a resulting decrease in flow resistance. The decrease in velocity towards the channel boundaries is also observed in this Figure 3 depicts that an increase in the value of Jeffery fluid parameter () causes a reduction in velocity. It is because by increasing the viscous effects dominate at the centre of the channel. Due to the classical effect of Hartmann number, it is obvious that an increase in the value of causes a decrease in velocity profile as illustrated in Figure 4. As Lorentz force (a resistive force) is present in MHD phenomena, thus by increasing the Lorentz force produce more resistance to the fluid flow due to which velocity decreases.

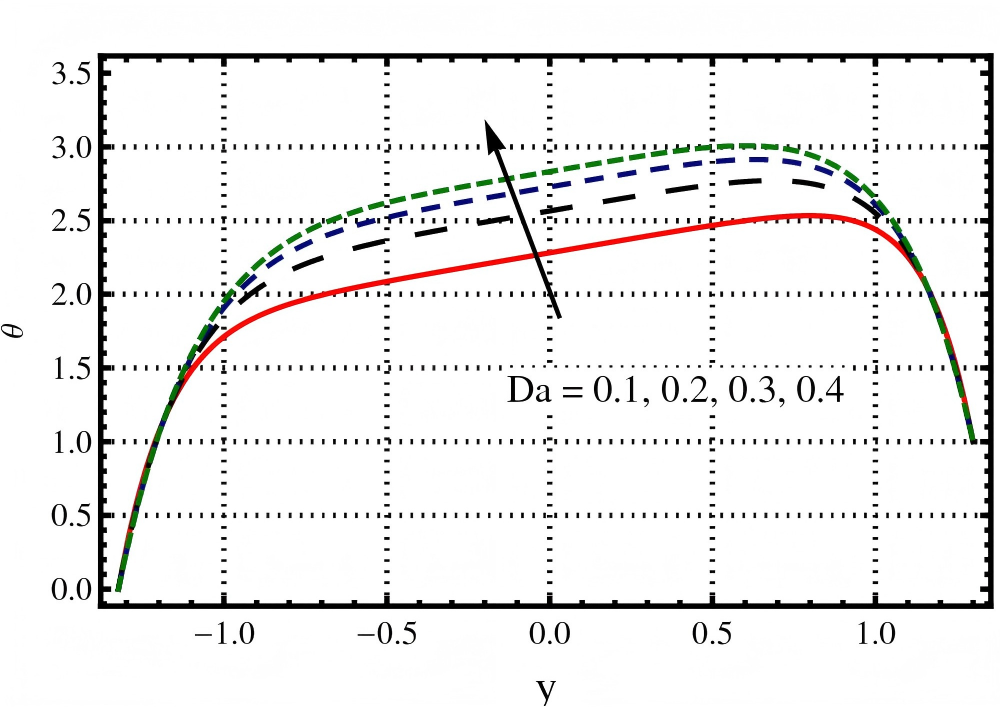

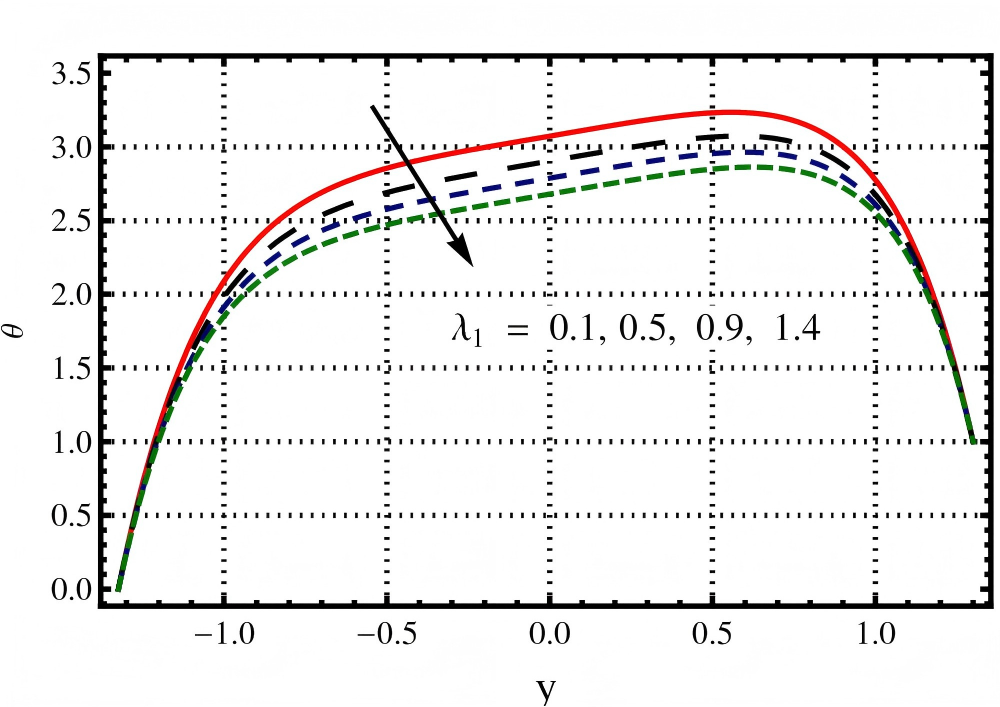

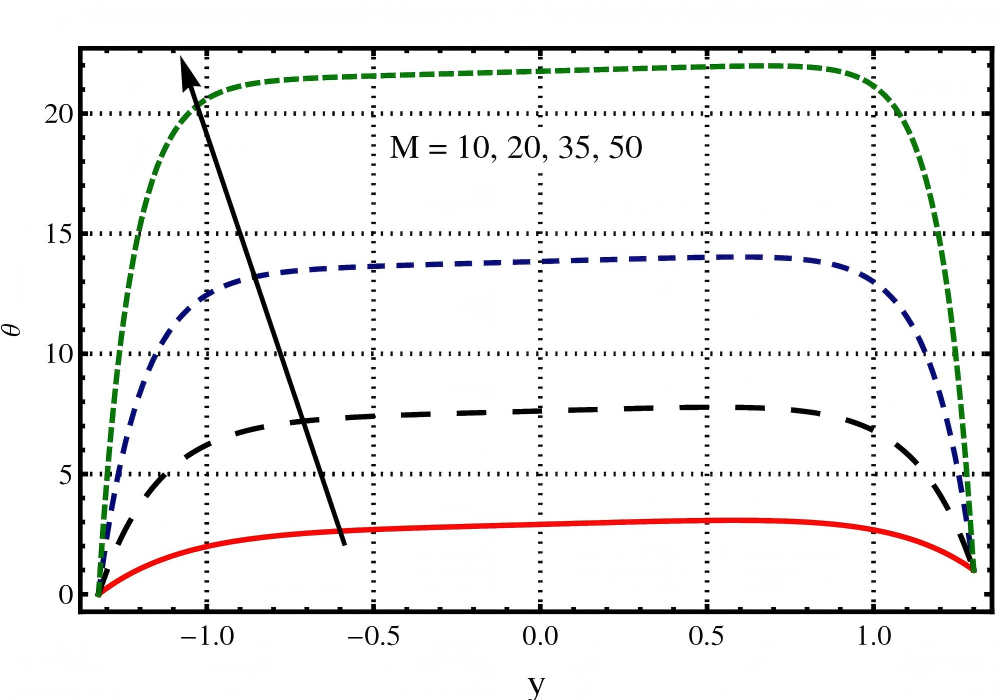

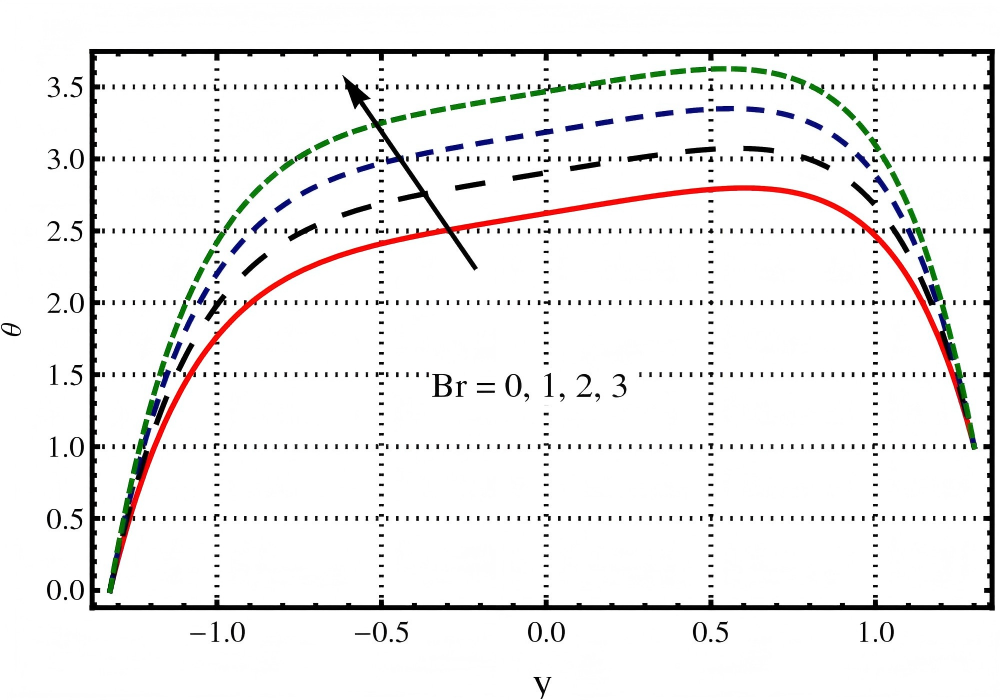

The impact of , , , on temperature profile (a resistive force) through Figures 5, 6, 7 and 8. In this section it is observed from Figure 5 that the profile for temperature distribution increases with an increase in the value of Darcy number (). Figure 6 depicts that an increase in the value of Jeffery fluid parameter () causes a reduction in temperature. Figure 7 depicts that higher increase in the value of Hartmann number () causes an increase in temperature. Figure 8 depicts that an increase in the value of Brinkman number () causes an increase in temperature. It is observed through these Figures 5, 6, 7 and 8 that temperature increases because of resistive characteristics of , , and parameters.

The key findings of this study are: 1. The velocity changes for modified Darcy parameter. 2. The Hartmann boundary layer increases for increasing . 3. For higher temperature decays. 4. Both Magnetic and Darcy parameter enhances the temperature.

Copyright © 2025 by the Author(s). Published by Institute of Central Computation and Knowledge. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made.

Copyright © 2025 by the Author(s). Published by Institute of Central Computation and Knowledge. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made.

Portico

All published articles are preserved here permanently:

https://www.portico.org/publishers/icck/