Journal of Advanced Electronic Materials

ISSN: pending (Online) | ISSN: pending (Print)

Email: [email protected]

Submit Manuscript

Edit a Special Issue

Submit Manuscript

Edit a Special Issue

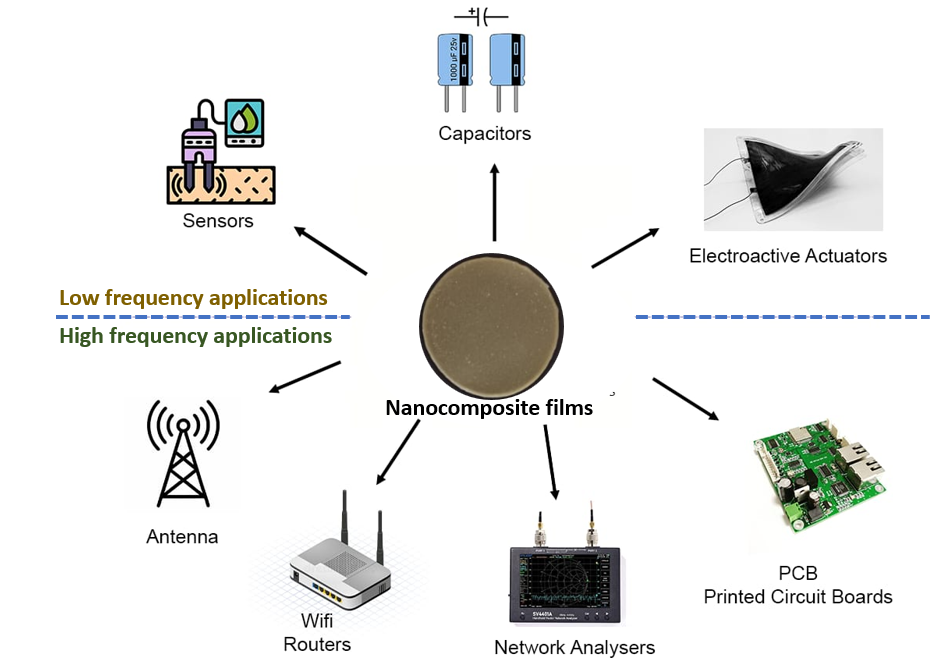

TY - JOUR AU - Jothiprakash, Gitanjali AU - Sun, Dongyang AU - Adonteng, Peter AU - See, Chan Hwang AU - Lasseuguette, Elsa AU - Lu, Zhilun AU - Desikan, Ramesh AU - Karthikeyan, Subburamu AU - Sundaram, Senthilarasu PY - 2025 DA - 2025/11/29 TI - Sustainable Nanocellulose-PEO Composites Reinforced with Functional Nanofillers in High-Performance Dielectric Nanocomposites for Green Flexible Electronics JO - Journal of Advanced Electronic Materials T2 - Journal of Advanced Electronic Materials JF - Journal of Advanced Electronic Materials VL - 1 IS - 1 SP - 5 EP - 16 DO - 10.62762/JAEM.2025.761770 UR - https://www.icck.org/article/abs/JAEM.2025.761770 KW - cellulose KW - nanofibrils KW - nanocomposite films KW - sustainable materials KW - water hyacinth AB - The growing demand for sustainable materials in green flexible electronics calls for alternatives to petroleum-derived polymers, which are non-biodegradable, resource-intensive, and environmentally harmful. This study presents the fabrication of bio-composite films using water hyacinth derived cellulose nanofibrils (CNF), blended with polyethylene oxide (PEO) and reinforced by functional nanofillers such as barium titanate (BTO), silver nanowires (SNP), and carbon nanotubes (CNT). The nanocomposite films (NCF) were produced by solution casting and systematically characterized for morphological, dielectric, mechanical, thermal, and chemical properties. Scanning electron microscopy analysis revealed well-dispersed CNF (-30 nm diameter) uniformly embedded within a CNF/PEO matrix and nanofillers (0.5–2%). Dielectric testing showed that BTO significantly enhanced permittivity (>200), making it promising for capacitor and antenna applications, although dielectric loss increased at higher nanofiller loadings. SNP-reinforced NCF exhibited moderate permittivity (50–90) but higher dielectric loss (0.15–0.32), supporting multifunctional applications requiring both dielectric and conductivity. CNT reinforced with NCF provided a balanced performance, with stable permittivity, relative low dielectric loss (< 0.015) and superior mechanical flexibility. Mechanical testing confirmed that BTO increased stiffness and tensile strength (1.5–2%), SNP enhanced strength but reduced ductility up to 1.5%, and CNT offered reinforcement at 1.5% with preserved elongation (up to 6%). FTIR spectra indicated strong interfacial interactions between nanofillers and CNF-PEO matrix. Thermal analysis revealed that CNT disrupted the crystalline structure of the matrix, lowering melting and crystallization temperatures, whereas BTO and SNP had negligible thermal effects. This study demonstrates a sustainable pathway to valorize an invasive species into a biodegradable, high-performance NCF for sustainable electronics, signifying a pathway toward flexible antenna, sensors, and energy storage materials. SN - pending PB - Institute of Central Computation and Knowledge LA - English ER -

@article{Jothiprakash2025Sustainabl,

author = {Gitanjali Jothiprakash and Dongyang Sun and Peter Adonteng and Chan Hwang See and Elsa Lasseuguette and Zhilun Lu and Ramesh Desikan and Subburamu Karthikeyan and Senthilarasu Sundaram},

title = {Sustainable Nanocellulose-PEO Composites Reinforced with Functional Nanofillers in High-Performance Dielectric Nanocomposites for Green Flexible Electronics},

journal = {Journal of Advanced Electronic Materials},

year = {2025},

volume = {1},

number = {1},

pages = {5-16},

doi = {10.62762/JAEM.2025.761770},

url = {https://www.icck.org/article/abs/JAEM.2025.761770},

abstract = {The growing demand for sustainable materials in green flexible electronics calls for alternatives to petroleum-derived polymers, which are non-biodegradable, resource-intensive, and environmentally harmful. This study presents the fabrication of bio-composite films using water hyacinth derived cellulose nanofibrils (CNF), blended with polyethylene oxide (PEO) and reinforced by functional nanofillers such as barium titanate (BTO), silver nanowires (SNP), and carbon nanotubes (CNT). The nanocomposite films (NCF) were produced by solution casting and systematically characterized for morphological, dielectric, mechanical, thermal, and chemical properties. Scanning electron microscopy analysis revealed well-dispersed CNF (-30 nm diameter) uniformly embedded within a CNF/PEO matrix and nanofillers (0.5–2\%). Dielectric testing showed that BTO significantly enhanced permittivity (>200), making it promising for capacitor and antenna applications, although dielectric loss increased at higher nanofiller loadings. SNP-reinforced NCF exhibited moderate permittivity (50–90) but higher dielectric loss (0.15–0.32), supporting multifunctional applications requiring both dielectric and conductivity. CNT reinforced with NCF provided a balanced performance, with stable permittivity, relative low dielectric loss (< 0.015) and superior mechanical flexibility. Mechanical testing confirmed that BTO increased stiffness and tensile strength (1.5–2\%), SNP enhanced strength but reduced ductility up to 1.5\%, and CNT offered reinforcement at 1.5\% with preserved elongation (up to 6\%). FTIR spectra indicated strong interfacial interactions between nanofillers and CNF-PEO matrix. Thermal analysis revealed that CNT disrupted the crystalline structure of the matrix, lowering melting and crystallization temperatures, whereas BTO and SNP had negligible thermal effects. This study demonstrates a sustainable pathway to valorize an invasive species into a biodegradable, high-performance NCF for sustainable electronics, signifying a pathway toward flexible antenna, sensors, and energy storage materials.},

keywords = {cellulose, nanofibrils, nanocomposite films, sustainable materials, water hyacinth},

issn = {pending},

publisher = {Institute of Central Computation and Knowledge}

}

Copyright © 2025 by the Author(s). Published by Institute of Central Computation and Knowledge. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made.

Copyright © 2025 by the Author(s). Published by Institute of Central Computation and Knowledge. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. Journal of Advanced Electronic Materials

ISSN: pending (Online) | ISSN: pending (Print)

Email: [email protected]

Portico

All published articles are preserved here permanently:

https://www.portico.org/publishers/icck/