Journal of Advanced Materials Research

ISSN: 3070-5851 (Online)

Email: [email protected]

Submit Manuscript

Edit a Special Issue

Submit Manuscript

Edit a Special Issue

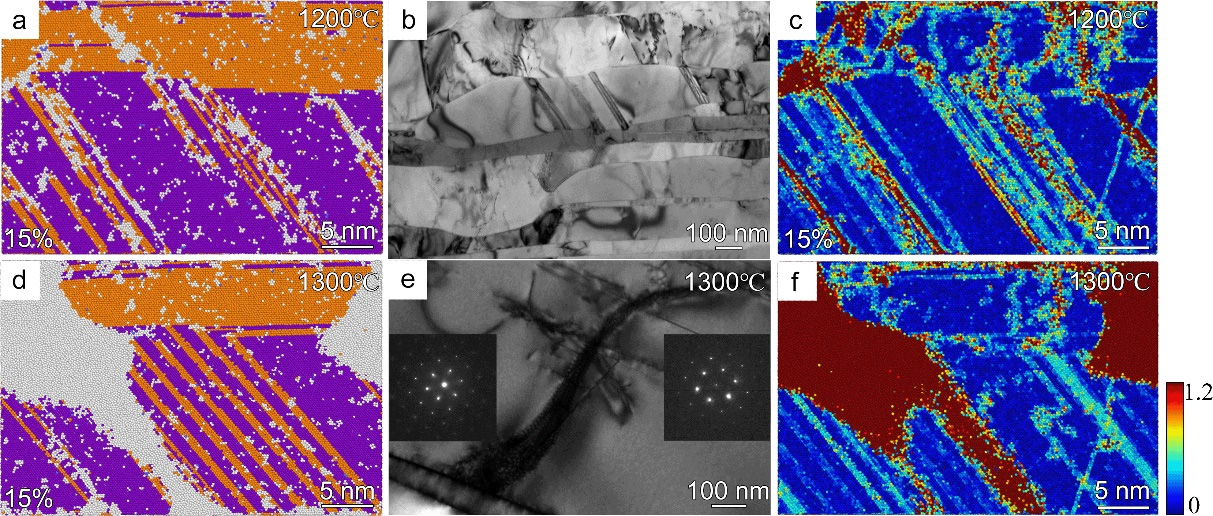

TY - JOUR AU - Xiang, Henggao AU - Zhu, Demin AU - Liu, Xu AU - Chen, Yang AU - Qi, Zhixiang AU - Chen, Guang PY - 2025 DA - 2025/12/29 TI - Lamellar Degradation Induced Brittle-ductile Transition of Polysynthetic Twinned TiAl JO - Journal of Advanced Materials Research T2 - Journal of Advanced Materials Research JF - Journal of Advanced Materials Research VL - 1 IS - 1 SP - 56 EP - 68 DO - 10.62762/JAMR.2025.522742 UR - https://www.icck.org/article/abs/JAMR.2025.522742 KW - polysynthetic twinned TiAl KW - brittle-ductile transition KW - lamellar degradation KW - high temperature strength AB - Intermetallic compounds including TiAl and NiAl suffer from an abrupt brittle-ductile transition at a critical temperature, limiting their higher temperature applications. Conventional viewpoints attribute this transition to thermally activated dislocation actions or dynamic recrystallization. Here, we discover a novel brittle-ductile transition mechanism in polysynthetic twinned TiAl, driven by lamellar degradation, which significantly deviates from the conventional mechanisms. The results demonstrate that the lamellar degradation is primarily caused by the \( \alpha_2 \rightarrow \gamma \) phase transformation at the brittle-ductile transition temperature, which stems from a non-monotonic increase in the stacking fault energy of \( \alpha_2 \) phase with temperature. This unconventional transition can be described efficiently by an energy density-based strength model, offering new insights into the brittle-ductile transition behavior of intermetallic compounds at elevated temperatures. SN - 3070-5851 PB - Institute of Central Computation and Knowledge LA - English ER -

@article{Xiang2025Lamellar,

author = {Henggao Xiang and Demin Zhu and Xu Liu and Yang Chen and Zhixiang Qi and Guang Chen},

title = {Lamellar Degradation Induced Brittle-ductile Transition of Polysynthetic Twinned TiAl},

journal = {Journal of Advanced Materials Research},

year = {2025},

volume = {1},

number = {1},

pages = {56-68},

doi = {10.62762/JAMR.2025.522742},

url = {https://www.icck.org/article/abs/JAMR.2025.522742},

abstract = {Intermetallic compounds including TiAl and NiAl suffer from an abrupt brittle-ductile transition at a critical temperature, limiting their higher temperature applications. Conventional viewpoints attribute this transition to thermally activated dislocation actions or dynamic recrystallization. Here, we discover a novel brittle-ductile transition mechanism in polysynthetic twinned TiAl, driven by lamellar degradation, which significantly deviates from the conventional mechanisms. The results demonstrate that the lamellar degradation is primarily caused by the \( \alpha\_2 \rightarrow \gamma \) phase transformation at the brittle-ductile transition temperature, which stems from a non-monotonic increase in the stacking fault energy of \( \alpha\_2 \) phase with temperature. This unconventional transition can be described efficiently by an energy density-based strength model, offering new insights into the brittle-ductile transition behavior of intermetallic compounds at elevated temperatures.},

keywords = {polysynthetic twinned TiAl, brittle-ductile transition, lamellar degradation, high temperature strength},

issn = {3070-5851},

publisher = {Institute of Central Computation and Knowledge}

}

Copyright © 2025 by the Author(s). Published by Institute of Central Computation and Knowledge. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made.

Copyright © 2025 by the Author(s). Published by Institute of Central Computation and Knowledge. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made.

Portico

All published articles are preserved here permanently:

https://www.portico.org/publishers/icck/