Journal of Advanced Materials Research

ISSN: 3070-5851 (Online)

Email: [email protected]

Submit Manuscript

Edit a Special Issue

Submit Manuscript

Edit a Special Issue

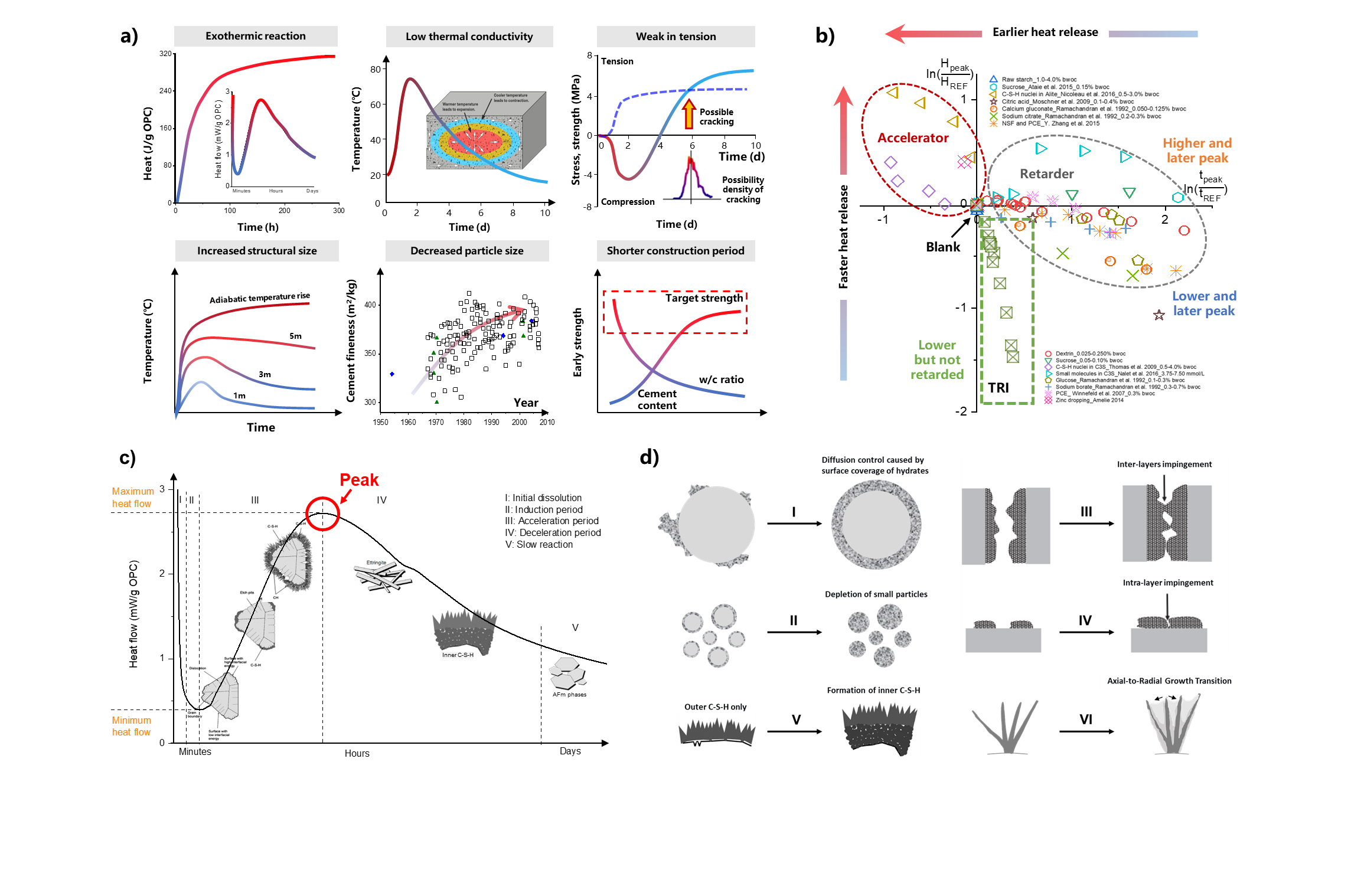

TY - JOUR AU - Yan, Yu AU - Zhou, Yichuan AU - Wang, Wenbin AU - He, Junhui AU - Wang, Rui PY - 2026 DA - 2026/01/21 TI - Mitigating Thermal Cracking in Mass Concrete with Temperature Rise Inhibitor: A Sustainable and Efficient Strategy JO - Journal of Advanced Materials Research T2 - Journal of Advanced Materials Research JF - Journal of Advanced Materials Research VL - 2 IS - 1 SP - 8 EP - 13 DO - 10.62762/JAMR.2025.738370 UR - https://www.icck.org/article/abs/JAMR.2025.738370 KW - mass concrete KW - chemical admixture KW - starch KW - cement hydration AB - Thermal cracking poses a significant threat to the structural integrity and service life of mass concrete. The starch-based Temperature Rise Inhibitor (TRI) emerges as a sustainable and efficient bio-based solution that directly addresses the root cause - the intense heat release during early-age cement hydration. Unlike conventional chemical admixtures, TRI features a special "controlled dissolution" mechanism in the high-pH environment of cement paste. This characteristic ensures a continuous release of organic molecules that selectively inhibit the nucleation of calcium silicate hydrates (C-S-H) gel, the primary hydrates of cement hydration. Consequently, TRI significantly slow down the heat release during the first 24 hours after casting without substantially delaying the setting time or compromising long-term strength gain. Here, we highlight the exceptional efficacy of TRI in regulating exothermic process of cement hydration, discussing mechanisms in cement and blended systems and the main challenges regarding their molecular-scale interaction with C-S-H nucleation. As discussed in this perspective, TRI exemplifies the potential of sustainable materials to address fundamental engineering challenges, bridging environmental responsibility with high performance in modern concrete. SN - 3070-5851 PB - Institute of Central Computation and Knowledge LA - English ER -

@article{Yan2026Mitigating,

author = {Yu Yan and Yichuan Zhou and Wenbin Wang and Junhui He and Rui Wang},

title = {Mitigating Thermal Cracking in Mass Concrete with Temperature Rise Inhibitor: A Sustainable and Efficient Strategy},

journal = {Journal of Advanced Materials Research},

year = {2026},

volume = {2},

number = {1},

pages = {8-13},

doi = {10.62762/JAMR.2025.738370},

url = {https://www.icck.org/article/abs/JAMR.2025.738370},

abstract = {Thermal cracking poses a significant threat to the structural integrity and service life of mass concrete. The starch-based Temperature Rise Inhibitor (TRI) emerges as a sustainable and efficient bio-based solution that directly addresses the root cause - the intense heat release during early-age cement hydration. Unlike conventional chemical admixtures, TRI features a special "controlled dissolution" mechanism in the high-pH environment of cement paste. This characteristic ensures a continuous release of organic molecules that selectively inhibit the nucleation of calcium silicate hydrates (C-S-H) gel, the primary hydrates of cement hydration. Consequently, TRI significantly slow down the heat release during the first 24 hours after casting without substantially delaying the setting time or compromising long-term strength gain. Here, we highlight the exceptional efficacy of TRI in regulating exothermic process of cement hydration, discussing mechanisms in cement and blended systems and the main challenges regarding their molecular-scale interaction with C-S-H nucleation. As discussed in this perspective, TRI exemplifies the potential of sustainable materials to address fundamental engineering challenges, bridging environmental responsibility with high performance in modern concrete.},

keywords = {mass concrete, chemical admixture, starch, cement hydration},

issn = {3070-5851},

publisher = {Institute of Central Computation and Knowledge}

}

Copyright © 2026 by the Author(s). Published by Institute of Central Computation and Knowledge. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made.

Copyright © 2026 by the Author(s). Published by Institute of Central Computation and Knowledge. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made.

Portico

All published articles are preserved here permanently:

https://www.portico.org/publishers/icck/