Reservoir Science

ISSN: 3070-2356 (Online)

Email: [email protected]

Submit Manuscript

Edit a Special Issue

Submit Manuscript

Edit a Special Issue

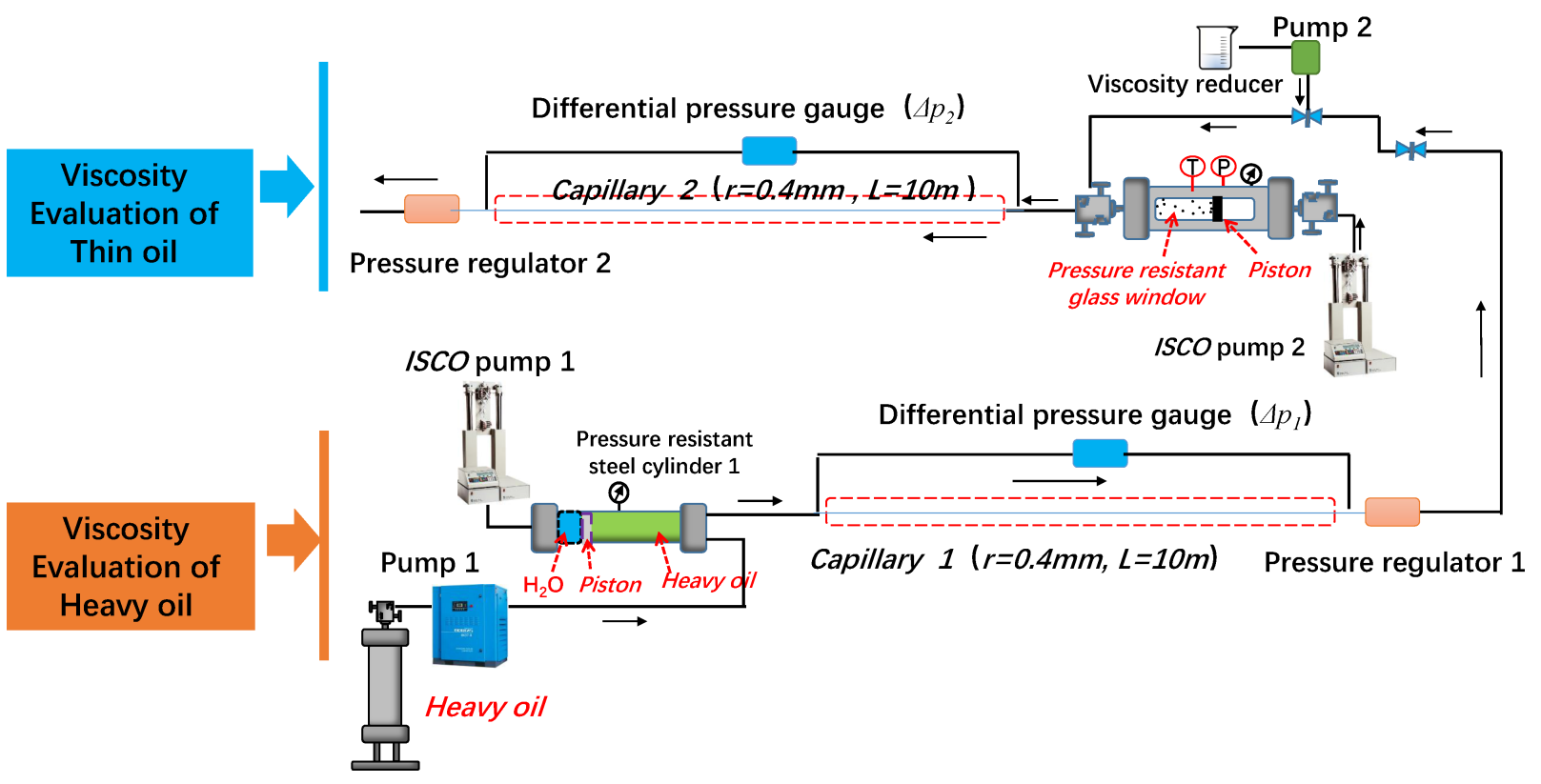

TY - JOUR AU - Xu, Ning AU - Wang, Yanling PY - 2026 DA - 2026/01/06 TI - Effect of Nanomaterials on Improving the Apparent Viscosity of Heavy Oil and the Environmental Evaluation of Reservoir Environment JO - Reservoir Science T2 - Reservoir Science JF - Reservoir Science VL - 2 IS - 1 SP - 1 EP - 15 DO - 10.62762/RS.2025.277961 UR - https://www.icck.org/article/abs/RS.2025.277961 KW - geological energy KW - geological reservoir KW - heavy oil viscosity reduction KW - reservoir stimulation KW - petroleum engineering AB - Heavy oil reservoirs have become an important potential for alleviating energy shortages and supporting economic development. This investigation aims to explore the influence of a nano heavy oil viscosity reducer and reservoir characteristics on crude oil viscosity and flow rate during the underground extraction process, and to reveal the viscosity reduction mechanism of reservoir crude oil. The results indicate that the prepared nano viscosity reducer can significantly weaken oil viscosity compared with the commercial viscosity reducer. Moreover, the nano viscosity reducer NVR (acting as a catalyst) achieves a much higher viscosity reduction performance than the commercial viscosity reducer CVR under the same conditions. Meanwhile, the dosage of nano viscosity reducer NVR shows the greatest impact on the viscosity reduction rate among the investigated factors, whereas the pyrolysis time exhibits the smallest influence. This investigation provides basic data for improving the flowability, mobility, and recovery of reservoir crude oil. SN - 3070-2356 PB - Institute of Central Computation and Knowledge LA - English ER -

@article{Xu2026Effect,

author = {Ning Xu and Yanling Wang},

title = {Effect of Nanomaterials on Improving the Apparent Viscosity of Heavy Oil and the Environmental Evaluation of Reservoir Environment},

journal = {Reservoir Science},

year = {2026},

volume = {2},

number = {1},

pages = {1-15},

doi = {10.62762/RS.2025.277961},

url = {https://www.icck.org/article/abs/RS.2025.277961},

abstract = {Heavy oil reservoirs have become an important potential for alleviating energy shortages and supporting economic development. This investigation aims to explore the influence of a nano heavy oil viscosity reducer and reservoir characteristics on crude oil viscosity and flow rate during the underground extraction process, and to reveal the viscosity reduction mechanism of reservoir crude oil. The results indicate that the prepared nano viscosity reducer can significantly weaken oil viscosity compared with the commercial viscosity reducer. Moreover, the nano viscosity reducer NVR (acting as a catalyst) achieves a much higher viscosity reduction performance than the commercial viscosity reducer CVR under the same conditions. Meanwhile, the dosage of nano viscosity reducer NVR shows the greatest impact on the viscosity reduction rate among the investigated factors, whereas the pyrolysis time exhibits the smallest influence. This investigation provides basic data for improving the flowability, mobility, and recovery of reservoir crude oil.},

keywords = {geological energy, geological reservoir, heavy oil viscosity reduction, reservoir stimulation, petroleum engineering},

issn = {3070-2356},

publisher = {Institute of Central Computation and Knowledge}

}

Copyright © 2026 by the Author(s). Published by Institute of Central Computation and Knowledge. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made.

Copyright © 2026 by the Author(s). Published by Institute of Central Computation and Knowledge. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made.

Portico

All published articles are preserved here permanently:

https://www.portico.org/publishers/icck/