ICCK Transactions on Intelligent Cyber-Physical Systems

ISSN: pending (Online)

Email: [email protected]

Submit Manuscript

Edit a Special Issue

Submit Manuscript

Edit a Special Issue

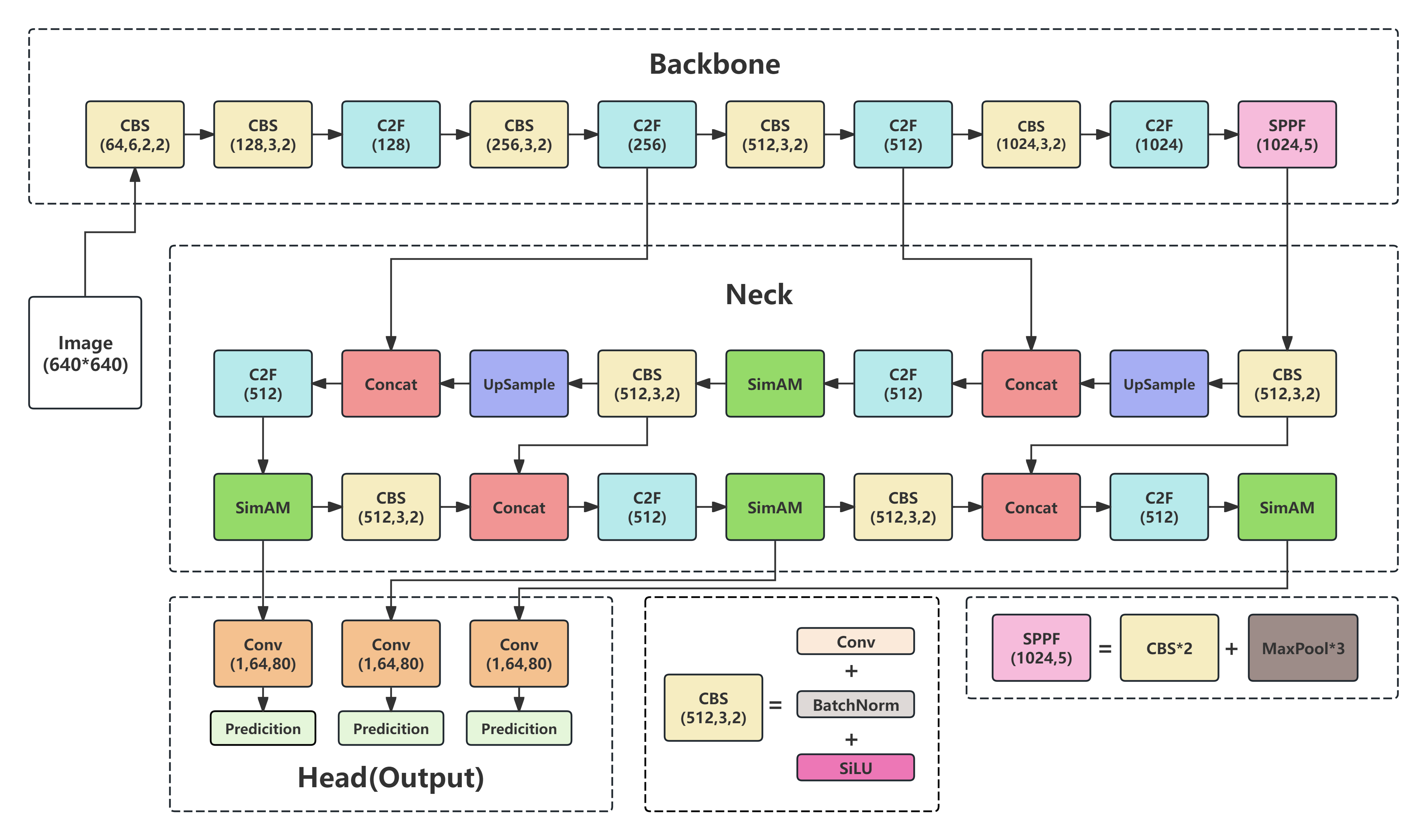

TY - JOUR AU - Lin, Liwei PY - 2026 DA - 2026/02/09 TI - Surface Defect Detection and Size Measurement of Bearings Based on Machine Vision JO - ICCK Transactions on Intelligent Cyber-Physical Systems T2 - ICCK Transactions on Intelligent Cyber-Physical Systems JF - ICCK Transactions on Intelligent Cyber-Physical Systems VL - 1 IS - 1 SP - 10 EP - 25 DO - 10.62762/TICPS.2025.819879 UR - https://www.icck.org/article/abs/TICPS.2025.819879 KW - bearing detection KW - YOLOv5 KW - C2F network KW - SimAM attention mechanism KW - machine vision KW - size measurement AB - Aiming at the problems of low efficiency, strong subjectivity in traditional bearing surface defect detection and insufficient dimensional measurement accuracy, this paper proposes an integrated detection scheme SimAM-YOLO that combines the improved YOLOv5 algorithm with size measurement technology. Based on YOLOv5, the scheme replaces the original C3 module with the C2F network structure and embeds the SimAM attention mechanism to enhance the model's ability to extract defect features. Combined with OpenCV, it realizes the real-time measurement of the key dimension of bearing radius and constructs a visual system for bearing size measurement. Experimental results show that the improved model achieves an average detection precision of 86.03%, a recall rate of 78%, and an mAP-0.5 of 82.17% for bearing defects such as cracks, scratches, and grooves, which are 14.8%, 8.77%, and 9.2% higher than the original YOLOv5 respectively. The dimensional measurement error is controlled within ±0.000061mm, meeting the requirements of industrial detection. The system has high automation and strong real-time performance, can adapt to the detection needs of bearings of different specifications, and provides an efficient and reliable technical support for bearing quality control. SN - pending PB - Institute of Central Computation and Knowledge LA - English ER -

@article{Lin2026Surface,

author = {Liwei Lin},

title = {Surface Defect Detection and Size Measurement of Bearings Based on Machine Vision},

journal = {ICCK Transactions on Intelligent Cyber-Physical Systems},

year = {2026},

volume = {1},

number = {1},

pages = {10-25},

doi = {10.62762/TICPS.2025.819879},

url = {https://www.icck.org/article/abs/TICPS.2025.819879},

abstract = {Aiming at the problems of low efficiency, strong subjectivity in traditional bearing surface defect detection and insufficient dimensional measurement accuracy, this paper proposes an integrated detection scheme SimAM-YOLO that combines the improved YOLOv5 algorithm with size measurement technology. Based on YOLOv5, the scheme replaces the original C3 module with the C2F network structure and embeds the SimAM attention mechanism to enhance the model's ability to extract defect features. Combined with OpenCV, it realizes the real-time measurement of the key dimension of bearing radius and constructs a visual system for bearing size measurement. Experimental results show that the improved model achieves an average detection precision of 86.03\%, a recall rate of 78\%, and an mAP-0.5 of 82.17\% for bearing defects such as cracks, scratches, and grooves, which are 14.8\%, 8.77\%, and 9.2\% higher than the original YOLOv5 respectively. The dimensional measurement error is controlled within ±0.000061mm, meeting the requirements of industrial detection. The system has high automation and strong real-time performance, can adapt to the detection needs of bearings of different specifications, and provides an efficient and reliable technical support for bearing quality control.},

keywords = {bearing detection, YOLOv5, C2F network, SimAM attention mechanism, machine vision, size measurement},

issn = {pending},

publisher = {Institute of Central Computation and Knowledge}

}

ICCK Transactions on Intelligent Cyber-Physical Systems

ISSN: pending (Online)

Email: [email protected]

Portico

All published articles are preserved here permanently:

https://www.portico.org/publishers/icck/