Abstract

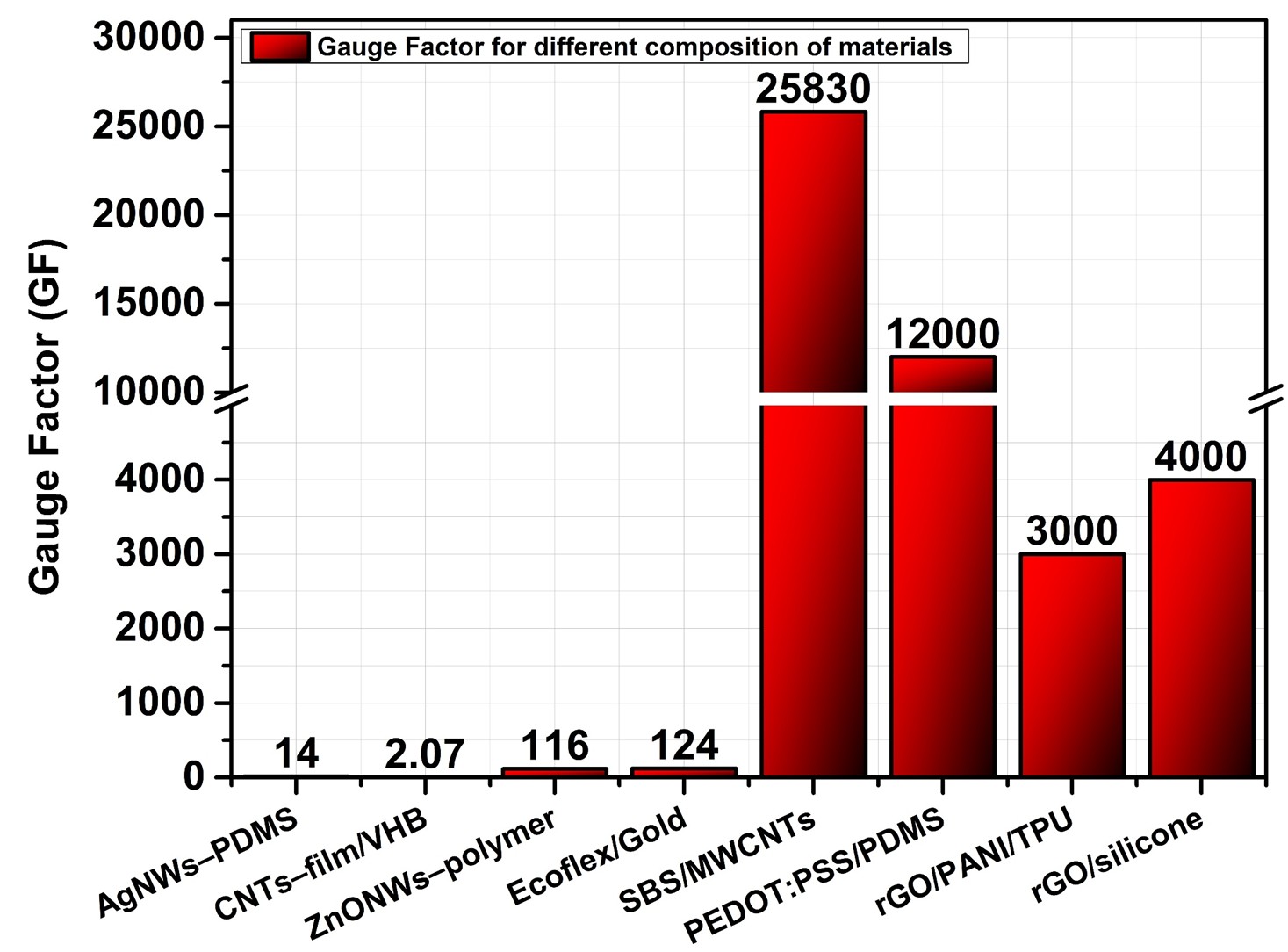

Strain sensors have become fundamental to contemporary sensing technology driven by the growing demand for flexible, sensitive, and durable sensors, transforming across a broad range of applications including medical care, robotics, structural monitoring, human-machine interface and robotics. The swift progress in the fields of materials and nanotechnology has facilitated the fabrication of very flexible, resilient, and ultra-sensitive strain sensors, enabling the emergence of next-generation electronic devices. This mini review covers sensors, strain sensors' fundamentals, classifications, innovative materials utilized, applications overall provide an in-depth analysis of the latest developments in strain sensor. Emerging materials that have together pushed the limits of sensor performance in terms of gauge factors, stretchability, reaction time, and durability are highlighted, including self-healing polymers, hybrid nanomaterials, graphene derivatives, carbon nanotube composites, and hydrogels. Even with impressive advancements, issues like biocompatibility, durability and many more factors continue to be major roadblocks to practical integration. Additionally, innovative solutions that enhance mechanical conformance and long-term stability are addressed in conjunction with challenges associated with packaging, integration, and other factors. This article offers a thorough roadmap for future research and real-world application of strain sensors in wearable electronics, soft robotics, and healthcare monitoring systems by combining recent literature and emphasizing important insights into the engineering of materials and functional performance. Finally, the analysis highlights emerging trends and possible prospects for next-generation strain sensing technologies that combine multi-functionality, self-healing, and scalable fabrication to fulfill real-world application demands.

Keywords

strain sensors

hydrogels

flexible wearable technology

biomedical applications

nano materials

polymers

Data Availability Statement

Not applicable.

Funding

This work was supported by the National Research Program for Universities- NRPU (20-15054/NRPU/R&D/HEC/2021 2021) funded by the Higher Education Commission, Pakistan.

Conflicts of Interest

The authors declare no conflicts of interest.

Ethical Approval and Consent to Participate

Not applicable.

Cite This Article

APA Style

Bibi, M., Hassan, G., Asif, A., Shuja, A., Ahmed, H., Mushtaq, B., & Sajid, M. (2025). Strain Sensing Technologies: Recent Developments in Materials, Performance, and Applications. ICCK Transactions on Sensing, Communication, and Control, 2(3), 168–199. https://doi.org/10.62762/TSCC.2025.665257

Publisher's Note

ICCK stays neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and Permissions

Institute of Central Computation and Knowledge (ICCK) or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

Submit Manuscript

Edit a Special Issue

Submit Manuscript

Edit a Special Issue