Agricultural Science and Food Processing

ISSN: 3066-1579 (Online) | ISSN: 3066-1560 (Print)

Email: [email protected]

Submit Manuscript

Edit a Special Issue

Submit Manuscript

Edit a Special Issue

TY - JOUR

AU - Nwakuba, Nnaemeka R.

AU - Ofojioha, Onyekachi M.

AU - Ikechukwu, Kingsley U.

AU - Ofoma, Angela N.

AU - Chikwue, Maxwell I.

AU - Oham, Preciouspaul N.

AU - Okorie, Chukwuebuka E.

PY - 2025

DA - 2025/12/30

TI - Development and Sustainability Assessment of a Fish-drying Kiln: Eco-thermodynamic Insights

JO - Agricultural Science and Food Processing

T2 - Agricultural Science and Food Processing

JF - Agricultural Science and Food Processing

VL - 2

IS - 4

SP - 176

EP - 196

DO - 10.62762/ASFP.2025.325927

UR - https://www.icck.org/article/abs/ASFP.2025.325927

KW - catfish

KW - specific energy utilization

KW - exergy efficiency

KW - sustainability metrics

KW - charcoal-powered dryer

KW - psychrometry

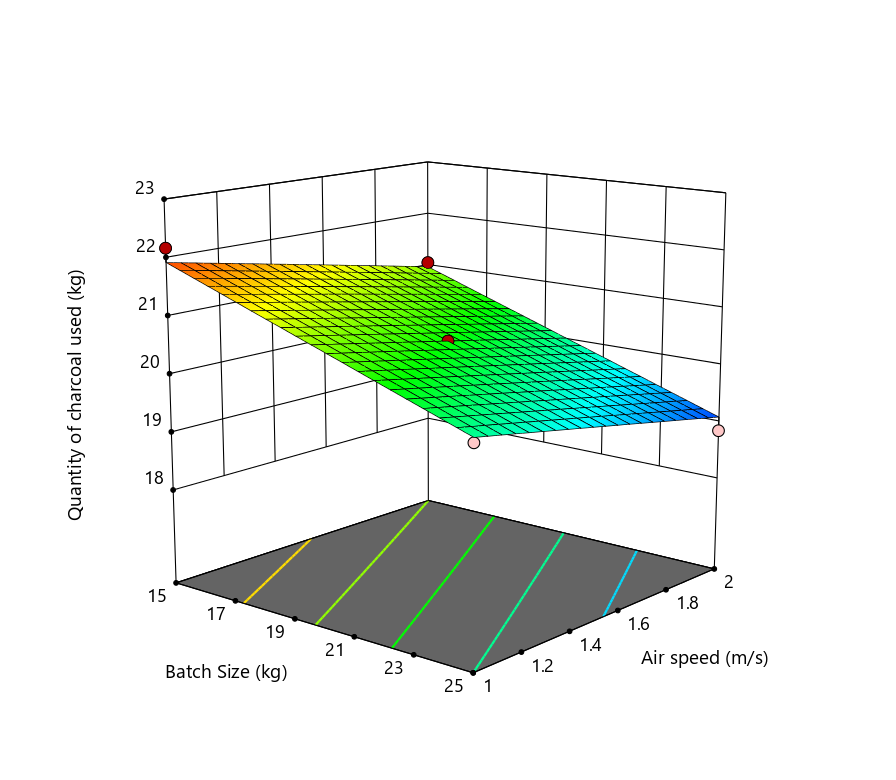

AB - The demand for sustainable and viable drying technologies has risen continuously in response to the growing energy costs and emerging environmental decline. The study designed and evaluated the operational efficiency of a counter-flow heat recovery fish drying kiln at a uniform temperature (55 $^\circ$C), varying air velocities (1.0, 1.5, and 2.0m/s), and batch sizes (15, 20, and 25kg) of catfish using an eco-thermodynamic approach embodying energy, exergy, environmental, and economic assessments. The findings indicate that heat transfer was greatly improved with higher air speeds and batch sizes, which also reduced charcoal consumption from 22.18kg to 18.85kg and shortened the drying duration from 330 to 180 minutes. The drying rate varied between 0.041 $\leq \mathcal{X}_d \leq$ 0.083kg/min, with a rehydration ratio of 1.71 $\leq \zeta_R \leq$ 1.74 and shrinkage of 20 $\leq \phi_s \leq$ 30.54$%$ ($\pm$ 2.25$%$). Specific energy utilization dropped from 42.88 $\times$ 10$^3$ to 21.87$\times$10$^3$ kJ/kg, and exergy efficiency increased from 42.88 $\leq \eta_{ex} \leq$ 49.75$%$ ($\pm$ 0.48$%$). The sustainability index and improvement potential were obtained as 1.68 and 457.48MJ, respectively. Environmental assessment enhanced as carbon credits rose to ₦532.33 and CO$_2$ emissions dropped from 62.77 kg to 53.35 kg/cycle. The kiln exhibited unique economic feasibility, as evidenced by the reduction in drying costs from ₦26.13 to ₦15.68/kg, and an increase in yearly savings from ₦3.88 million to ₦6.86 million. The benefit-cost ratio rose from 1.98 to 3.59, and the payback time was shortened to 0.27 years. These findings support the kiln’s potential as an inexpensive, ecologically friendly, and thermally productive solution for drying fish products. Future research directions were proposed.

SN - 3066-1579

PB - Institute of Central Computation and Knowledge

LA - English

ER -

@article{Nwakuba2025Developmen,

author = {Nnaemeka R. Nwakuba and Onyekachi M. Ofojioha and Kingsley U. Ikechukwu and Angela N. Ofoma and Maxwell I. Chikwue and Preciouspaul N. Oham and Chukwuebuka E. Okorie},

title = {Development and Sustainability Assessment of a Fish-drying Kiln: Eco-thermodynamic Insights},

journal = {Agricultural Science and Food Processing},

year = {2025},

volume = {2},

number = {4},

pages = {176-196},

doi = {10.62762/ASFP.2025.325927},

url = {https://www.icck.org/article/abs/ASFP.2025.325927},

abstract = {The demand for sustainable and viable drying technologies has risen continuously in response to the growing energy costs and emerging environmental decline. The study designed and evaluated the operational efficiency of a counter-flow heat recovery fish drying kiln at a uniform temperature (55 \$^\circ\$C), varying air velocities (1.0, 1.5, and 2.0m/s), and batch sizes (15, 20, and 25kg) of catfish using an eco-thermodynamic approach embodying energy, exergy, environmental, and economic assessments. The findings indicate that heat transfer was greatly improved with higher air speeds and batch sizes, which also reduced charcoal consumption from 22.18kg to 18.85kg and shortened the drying duration from 330 to 180 minutes. The drying rate varied between 0.041 \$\leq \mathcal{X}\_d \leq\$ 0.083kg/min, with a rehydration ratio of 1.71 \$\leq \zeta\_R \leq\$ 1.74 and shrinkage of 20 \$\leq \phi\_s \leq\$ 30.54\$\%\$ (\$\pm\$ 2.25\$\%\$). Specific energy utilization dropped from 42.88 \$\times\$ 10\$^3\$ to 21.87\$\times\$10\$^3\$ kJ/kg, and exergy efficiency increased from 42.88 \$\leq \eta\_{ex} \leq\$ 49.75\$\%\$ (\$\pm\$ 0.48\$\%\$). The sustainability index and improvement potential were obtained as 1.68 and 457.48MJ, respectively. Environmental assessment enhanced as carbon credits rose to ₦532.33 and CO\$\_2\$ emissions dropped from 62.77 kg to 53.35 kg/cycle. The kiln exhibited unique economic feasibility, as evidenced by the reduction in drying costs from ₦26.13 to ₦15.68/kg, and an increase in yearly savings from ₦3.88 million to ₦6.86 million. The benefit-cost ratio rose from 1.98 to 3.59, and the payback time was shortened to 0.27 years. These findings support the kiln’s potential as an inexpensive, ecologically friendly, and thermally productive solution for drying fish products. Future research directions were proposed.},

keywords = {catfish, specific energy utilization, exergy efficiency, sustainability metrics, charcoal-powered dryer, psychrometry},

issn = {3066-1579},

publisher = {Institute of Central Computation and Knowledge}

}

Copyright © 2025 by the Author(s). Published by Institute of Central Computation and Knowledge. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made.

Copyright © 2025 by the Author(s). Published by Institute of Central Computation and Knowledge. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. Agricultural Science and Food Processing

ISSN: 3066-1579 (Online) | ISSN: 3066-1560 (Print)

Email: [email protected]

Portico

All published articles are preserved here permanently:

https://www.portico.org/publishers/icck/