Abstract

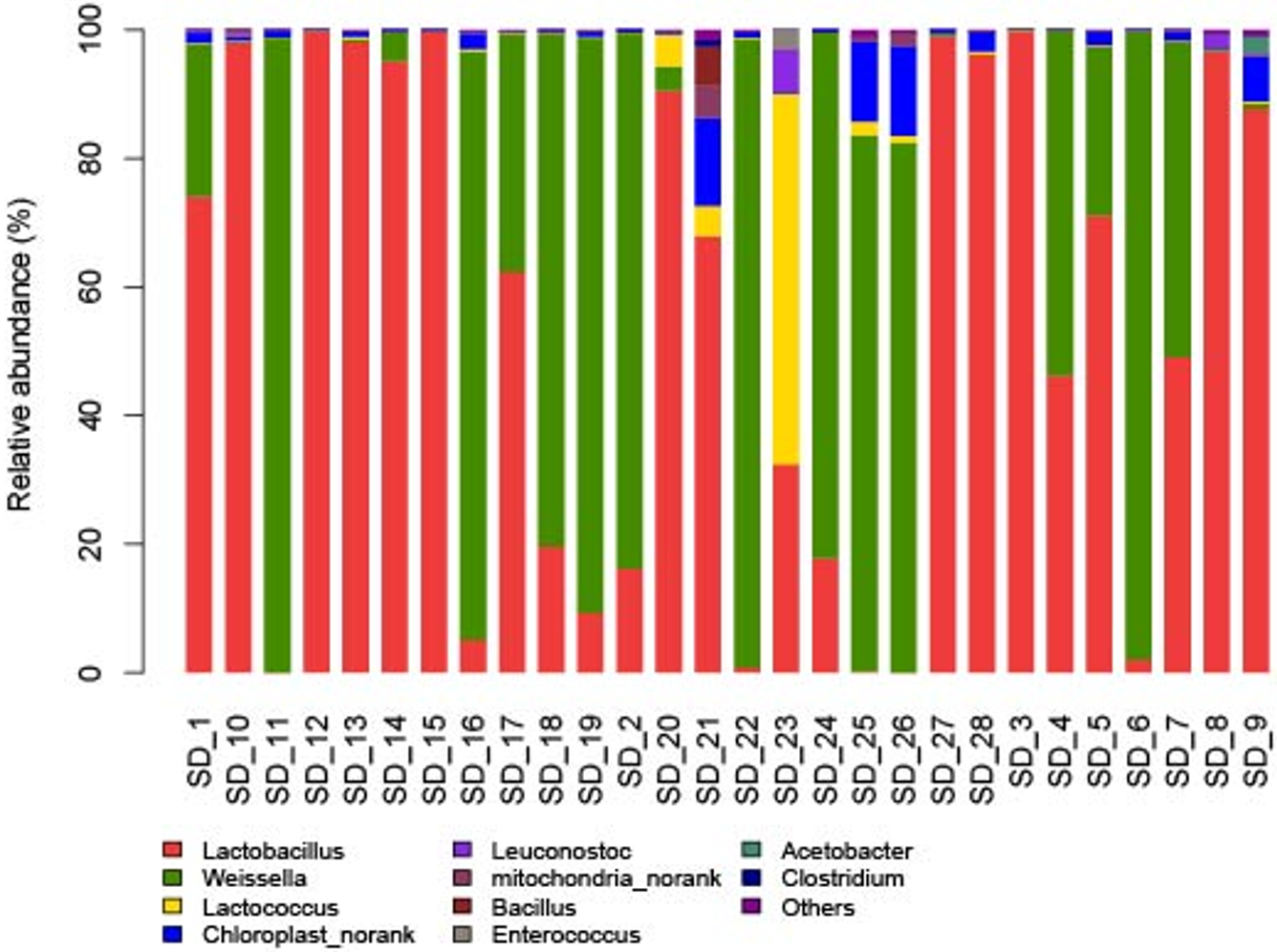

This study aims to figure out the structure of the microbial community in traditional sourdough and the different flavor components of Chinese steamed bread(CSB) made with it. The sourdough samples were selected from Shanxi, Henan and Shandong provinces. The microbial community composition of the sourdoughs was analyzed by a culture-dependent method and high-throughput sequencing, and the flavor compounds of the steamed breads were determined by the solid-phase micro extraction (SPME) method coupled with gas chromatography/mass spectroscopy (GC/MS). The results showed that: in the 28 samples collected, the pH ranged from 3.50 to 4.91, and the total titratable acid (TTA) values ranged from 2.50 to 7.80 mL of NaOH (1 M), while the total number of lactic acid bacteria (LAB) colonies ranged from 10^4 to 10^7 CFU/mL. Lactobacillus, Lactococcus, and Weissella were the dominant genera, as determined by pyrosequencing. A total of 180 LAB strains were isolated and identified using the 16S rRNA gene; the results indicate that Lactobacillus plantarum, Lactobacillus fermentum, and Weissella confusa were isolated with a relatively high frequency. By GC/MS, a total of 24 volatile compounds were detected, including hydrocarbons, aromatic compounds, alcohols, esters, aldehydes, acids, etc. Benzeneethanol and benzaldehyde were abundant in all five samples detected, while benzene-propoxyethyl was not detected in the control group.The flavor compounds contained in sourdough fermented CSBs, both in terms of quantity and concentration, are higher than those in yeast-fermented CSBs. This study provides a useful base for further exploring the deep connections between microbial communities and food flavors.

Data Availability Statement

Data will be made available on request.

Funding

This work was supported by the Academy of National Food and Strategic Reserves Administration of China under Grant ZX1509 and Grant ZX2454.

Conflicts of Interest

Xiaomin Li is an employee of COFCO Nutrition and Health Institute, Beijing 102209, China.

Ethical Approval and Consent to Participate

Not applicable.

Cite This Article

APA Style

Xue, Z., Han, W., Zhuang, X., Miao, H., Chen, H., Luo, X., & Li, X. (2025). Analysis of Sourdough’s Microbial Community and Flavor Components in Traditional Chinese Steamed Bread. Agricultural Science and Food Processing, 2(2), 106–115. https://doi.org/10.62762/ASFP.2025.520767

Publisher's Note

ICCK stays neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and Permissions

Copyright © 2025 by the Author(s). Published by Institute of Central Computation and Knowledge. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (

https://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made.

Submit Manuscript

Edit a Special Issue

Submit Manuscript

Edit a Special Issue

Copyright © 2025 by the Author(s). Published by Institute of Central Computation and Knowledge. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made.

Copyright © 2025 by the Author(s). Published by Institute of Central Computation and Knowledge. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made.