Journal of Advanced Materials Research

ISSN: 3070-5851 (Online)

Email: [email protected]

Submit Manuscript

Edit a Special Issue

Submit Manuscript

Edit a Special Issue

TY - JOUR

AU - Ye, Junhao

AU - Han, Weiwei

AU - Zhou, Zhenzhen

AU - Hu, Chen

AU - Liu, Yiyang

AU - Wu, Lexiang

AU - Huang, Dong

AU - Li, Tingsong

AU - Li, Jiang

PY - 2025

DA - 2025/12/20

TI - Highly Transparent Sm:LuAG Ceramics for Cladding Fabricated by Solid-state Reactive Sintering

JO - Journal of Advanced Materials Research

T2 - Journal of Advanced Materials Research

JF - Journal of Advanced Materials Research

VL - 1

IS - 1

SP - 6

EP - 17

DO - 10.62762/JAMR.2025.567536

UR - https://www.icck.org/article/abs/JAMR.2025.567536

KW - Sm:LuAG

KW - transparent ceramics

KW - cladding ceramics

KW - microstructure evolution

KW - sintering additives

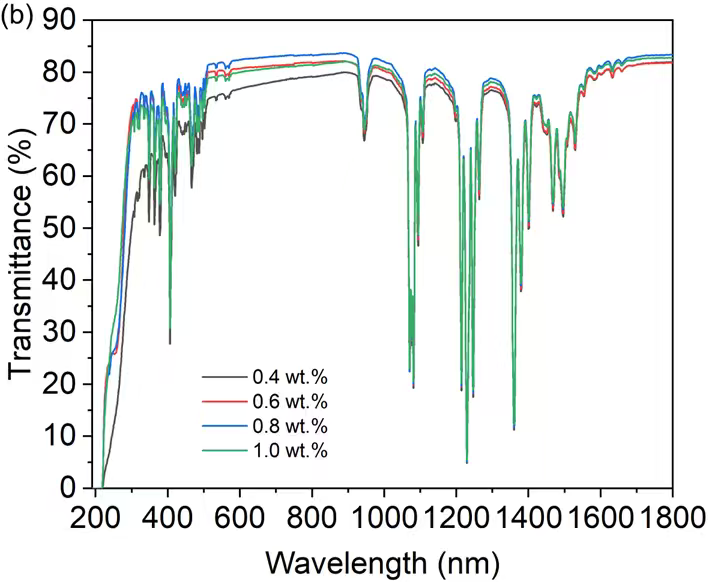

AB - In solid-state laser systems with nanosecond repetition rates and high energy, amplified spontaneous emission (ASE) and parasitic oscillation (PO) produced by the gain material can significantly impact the laser output. A well-designed cladding composite structure is an effective solution to absorb ASE and suppress PO. In this work, 5 at.% Sm:LuAG transparent ceramics, a promising cladding material for suppressors of PO at 1064 nm of Nd:LuAG lasers, have been prepared by solid-state reactive sintering at 1825 °C followed by hot isostatic pressing (HIP) post-treatment at 1750 °C. The influences of TEOS (tetraethyl orthosilicate) content on microstructure evolution, in-line transmittance of the 5 at.% Sm:LuAG ceramics were studied. The results show that when the TEOS content is 0.8 wt.%, high transparency Sm:LuAG ceramics can be obtained by vacuum sintering at 1825 °C for 5 h followed by HIP post-treatment at 1750 °C in an argon atmosphere under 200 MPa for 3 h. The optimum in-line transmittance of the HIP-ed Sm:LuAG ceramics (1.5 mm thickness) is 83.3% at a wavelength of 808 nm and absorption coefficient of 3.46 cm$^{-1}$ at 1064 nm, indicating that it can effectively suppress ASE and PO.

SN - 3070-5851

PB - Institute of Central Computation and Knowledge

LA - English

ER -

@article{Ye2025Highly,

author = {Junhao Ye and Weiwei Han and Zhenzhen Zhou and Chen Hu and Yiyang Liu and Lexiang Wu and Dong Huang and Tingsong Li and Jiang Li},

title = {Highly Transparent Sm:LuAG Ceramics for Cladding Fabricated by Solid-state Reactive Sintering},

journal = {Journal of Advanced Materials Research},

year = {2025},

volume = {1},

number = {1},

pages = {6-17},

doi = {10.62762/JAMR.2025.567536},

url = {https://www.icck.org/article/abs/JAMR.2025.567536},

abstract = {In solid-state laser systems with nanosecond repetition rates and high energy, amplified spontaneous emission (ASE) and parasitic oscillation (PO) produced by the gain material can significantly impact the laser output. A well-designed cladding composite structure is an effective solution to absorb ASE and suppress PO. In this work, 5 at.\% Sm:LuAG transparent ceramics, a promising cladding material for suppressors of PO at 1064 nm of Nd:LuAG lasers, have been prepared by solid-state reactive sintering at 1825 °C followed by hot isostatic pressing (HIP) post-treatment at 1750 °C. The influences of TEOS (tetraethyl orthosilicate) content on microstructure evolution, in-line transmittance of the 5 at.\% Sm:LuAG ceramics were studied. The results show that when the TEOS content is 0.8 wt.\%, high transparency Sm:LuAG ceramics can be obtained by vacuum sintering at 1825 °C for 5 h followed by HIP post-treatment at 1750 °C in an argon atmosphere under 200 MPa for 3 h. The optimum in-line transmittance of the HIP-ed Sm:LuAG ceramics (1.5 mm thickness) is 83.3\% at a wavelength of 808 nm and absorption coefficient of 3.46 cm\$^{-1}\$ at 1064 nm, indicating that it can effectively suppress ASE and PO.},

keywords = {Sm:LuAG, transparent ceramics, cladding ceramics, microstructure evolution, sintering additives},

issn = {3070-5851},

publisher = {Institute of Central Computation and Knowledge}

}

Copyright © 2025 by the Author(s). Published by Institute of Central Computation and Knowledge. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made.

Copyright © 2025 by the Author(s). Published by Institute of Central Computation and Knowledge. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made.

Portico

All published articles are preserved here permanently:

https://www.portico.org/publishers/icck/