Abstract

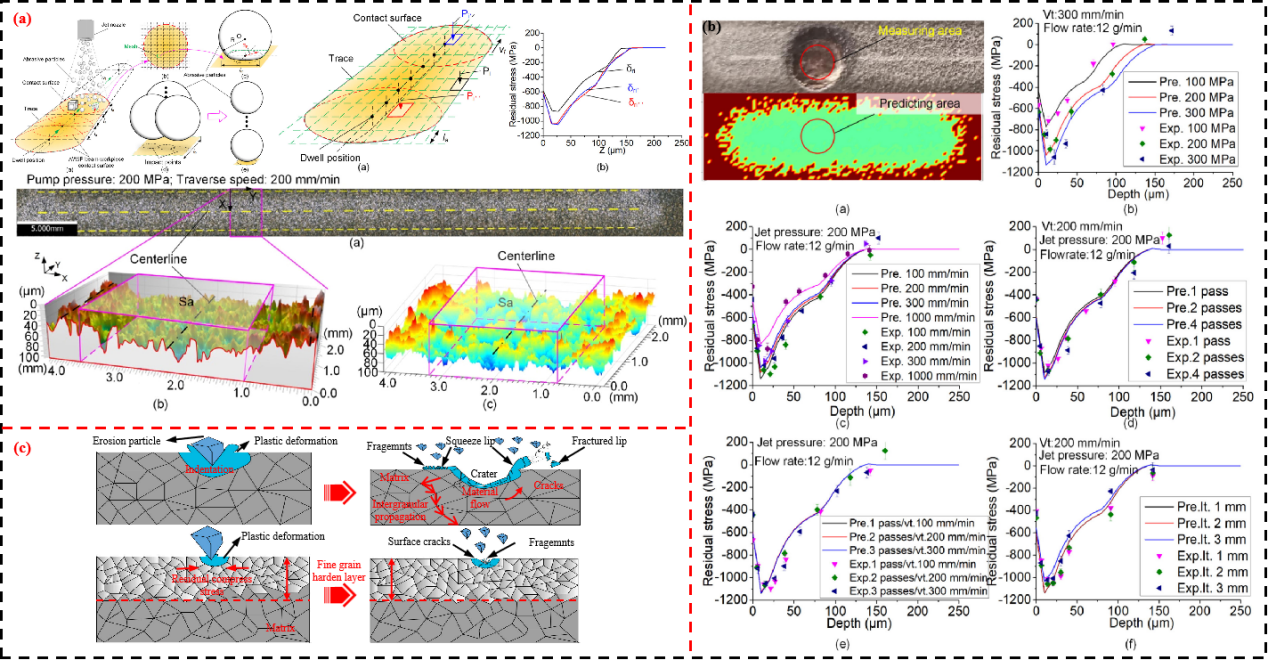

The water jet surface modification technology does not introduce thermal stress and thermal deformation during operation, reducing changes in the material's phase transformation temperature or grain growth, and avoiding problems related to thermal stress and deformation. It contains no chemical substances, posing no environmental pollution, and features low cost. It enables treatment of surfaces in narrow spaces, deep grooves, and on small components, and can operate under complex environmental conditions. Moreover, it is easy to mechanize and automate, showing great application prospects across many industries. This paper first reviews the development history and working principles of high-pressure water jet surface strengthening technology, explaining the mechanisms and recent research progress of abrasive water jet, cavitation water jet, and pulsed water jet technologies. It then summarizes the residual stress, grain refinement, fatigue life, and comparisons of internal and external flow field structures of different water jet surface modification techniques. Finally, it discusses the practical challenges of high-pressure water jet technology, such as poor workpiece surface quality, specific nozzle requirements, and nozzle wear.

Keywords

high-pressure water jet

fatigue life

residual stress

nozzle structure

internal and external flow field structure

Data Availability Statement

Not applicable.

Funding

This work was supported by the Natural Science Foundation of Shandong Province under Grant ZR2022QE149 and Grant ZR2023ME223.

Conflicts of Interest

The authors declare no conflicts of interest.

Ethical Approval and Consent to Participate

Not applicable.

Cite This Article

APA Style

Yue, X., Zhang, P., Gao, Y. & Wang, X. (2025). Research Progress, Challenges, and Prospects of High-Pressure Water Jet Surface Modification Technology for Aerospace Materials. Journal of Materials Durability and Engineering, 1(1), 4–22. https://doi.org/10.62762/JMDE.2025.954580

Publisher's Note

ICCK stays neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and Permissions

Copyright © 2025 by the Author(s). Published by Institute of Central Computation and Knowledge. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (

https://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made.

Submit Manuscript

Edit a Special Issue

Submit Manuscript

Edit a Special Issue

Copyright © 2025 by the Author(s). Published by Institute of Central Computation and Knowledge. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made.

Copyright © 2025 by the Author(s). Published by Institute of Central Computation and Knowledge. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made.