Abstract

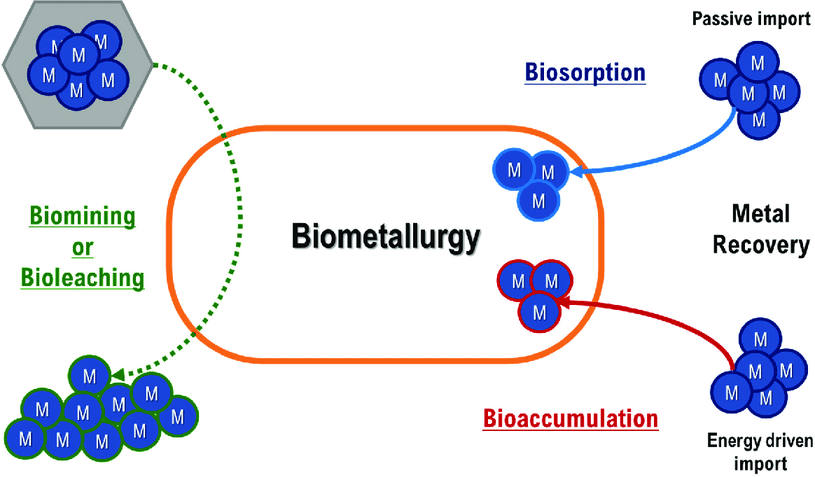

As new and innovative products with more functions, effectiveness and efficiency are introduced to the market continuously, the lifespan of existing products and equipment are becoming shorter and shorter before they are discarded. Therefore, significant amounts of electronic waste (e-waste) are mainly disposed of in the landfill. This study investigates the recycling of e-waste and recovering precious metals from computer components based on the information available in the literature. The manual dismantling, pre-processing and smelting techniques are discussed and elaborated. Among these techniques smelting/end-processes are employed to collect metals using several methods such as hydrometallurgy, pyrometallurgy and bio metallurgy are analysed critically. It was found that the dismantling techniques depends on the type of appliances, but the pre-processing techniques are almost independent on the appliance or types of metals to be collected. The smelting/end-processes and types of chemicals used depend on the metals to be recovered. The appropriate recycling processes and methods can be used to minimize the negative impacts that e-wastes have brought. In general, bio metallurgy is the most environmentally friendly technique to recover metals though this technique is very selective, less efficient and minor contaminating.

Data Availability Statement

Not applicable.

Funding

This work was supported without any funding.

Conflicts of Interest

The authors declare no conflicts of interest.

Ethical Approval and Consent to Participate

Not applicable.

Cite This Article

APA Style

Chan, C. K., Pramanik, A., Basak, A. K., & Shankar, S. (2025). Recycling of Materials from Computer Waste. ICCK Transactions on Advanced Functional Materials and Processing, 1(2), 32–46. https://doi.org/10.62762/TAFMP.2025.802278

Publisher's Note

ICCK stays neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and Permissions

Copyright © 2025 by the Author(s). Published by Institute of Central Computation and Knowledge. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (

https://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made.

Submit Manuscript

Edit a Special Issue

Submit Manuscript

Edit a Special Issue

Copyright © 2025 by the Author(s). Published by Institute of Central Computation and Knowledge. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made.

Copyright © 2025 by the Author(s). Published by Institute of Central Computation and Knowledge. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made.