Digital Intelligence in Agriculture

ISSN: 3069-3187 (Online)

Email: [email protected]

Submit Manuscript

Edit a Special Issue

Submit Manuscript

Edit a Special Issue

TY - JOUR

AU - Chen, Yifei

AU - Jiang, Li

AU - Wang, Shuo

AU - Luo, Wenjie

AU - Shoukat, Muhammad Rizwan

AU - Han, Mengxue

AU - Yang, Huimin

PY - 2025

DA - 2025/12/28

TI - Design and Testing of an Intelligent Cut-and-Harvest Machine for Apocynum Venetum

JO - Digital Intelligence in Agriculture

T2 - Digital Intelligence in Agriculture

JF - Digital Intelligence in Agriculture

VL - 1

IS - 2

SP - 96

EP - 109

DO - 10.62762/DIA.2025.327734

UR - https://www.icck.org/article/abs/DIA.2025.327734

KW - apocynum venetum

KW - cutting-bundling harvester

KW - bundling mechanism

KW - integrated navigation system

KW - mechanized harvesting

KW - anti-clogging conveyance

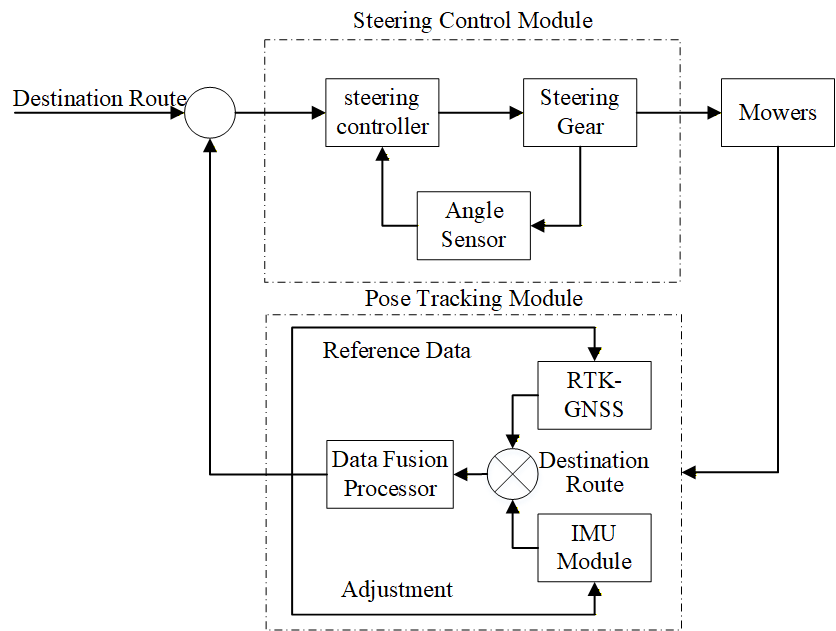

AB - Apocynum venetum has clustered, highly branched stems with strong phloem fiber adhesion, which makes mechanical harvesting prone to entanglement, grip slippage, conveyance blockage, and uneven, high stubble. Existing cutting and bundling machines do not match this morphology well and cannot meet both low-stubble and anti-clogging requirements. To address these problems, an integrated Apocynum venetum cutting-bundling harvester was developed that combines a reciprocating cutting mechanism, stem-folding assembly, vertical anti-clogging conveyor at the cutting table, height-adjustable crop-plate compaction device, and cord-based bundling mechanism, which was supported by a combined navigation system integrating BeiDou satellite navigation and inertial navigation. Field trials in Xinjiang demonstrated that the prototype achieved a mean stubble height of 12.4 cm, a blockage incidence of 0.30 events per hour, a bundling success rate of 98\%, a fiber damage rate of 0.8\% and a harvesting efficiency of 0.0537 ha h\(^{-1}\), meeting ISO 11279:2021 performance thresholds. The coordinated action of the cutting, folding, conveying, and bundling subsystems improved the throughput and maintained stable machine operation under clustered growth conditions. These results indicate that the developed prototype harvester is technically feasible and agronomically suitable for large-scale Apocynum venetum production. The intelligent Apocynum baling harvester can enhance the automatic driving functionality of agricultural machinery, improve the operational quality of agricultural machinery navigation, and thereby comprehensively increase harvesting efficiency.

SN - 3069-3187

PB - Institute of Central Computation and Knowledge

LA - English

ER -

@article{Chen2025Design,

author = {Yifei Chen and Li Jiang and Shuo Wang and Wenjie Luo and Muhammad Rizwan Shoukat and Mengxue Han and Huimin Yang},

title = {Design and Testing of an Intelligent Cut-and-Harvest Machine for Apocynum Venetum},

journal = {Digital Intelligence in Agriculture},

year = {2025},

volume = {1},

number = {2},

pages = {96-109},

doi = {10.62762/DIA.2025.327734},

url = {https://www.icck.org/article/abs/DIA.2025.327734},

abstract = {Apocynum venetum has clustered, highly branched stems with strong phloem fiber adhesion, which makes mechanical harvesting prone to entanglement, grip slippage, conveyance blockage, and uneven, high stubble. Existing cutting and bundling machines do not match this morphology well and cannot meet both low-stubble and anti-clogging requirements. To address these problems, an integrated Apocynum venetum cutting-bundling harvester was developed that combines a reciprocating cutting mechanism, stem-folding assembly, vertical anti-clogging conveyor at the cutting table, height-adjustable crop-plate compaction device, and cord-based bundling mechanism, which was supported by a combined navigation system integrating BeiDou satellite navigation and inertial navigation. Field trials in Xinjiang demonstrated that the prototype achieved a mean stubble height of 12.4 cm, a blockage incidence of 0.30 events per hour, a bundling success rate of 98\\%, a fiber damage rate of 0.8\\% and a harvesting efficiency of 0.0537 ha h\(^{-1}\), meeting ISO 11279:2021 performance thresholds. The coordinated action of the cutting, folding, conveying, and bundling subsystems improved the throughput and maintained stable machine operation under clustered growth conditions. These results indicate that the developed prototype harvester is technically feasible and agronomically suitable for large-scale Apocynum venetum production. The intelligent Apocynum baling harvester can enhance the automatic driving functionality of agricultural machinery, improve the operational quality of agricultural machinery navigation, and thereby comprehensively increase harvesting efficiency.},

keywords = {apocynum venetum, cutting-bundling harvester, bundling mechanism, integrated navigation system, mechanized harvesting, anti-clogging conveyance},

issn = {3069-3187},

publisher = {Institute of Central Computation and Knowledge}

}

Copyright © 2025 by the Author(s). Published by Institute of Central Computation and Knowledge. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made.

Copyright © 2025 by the Author(s). Published by Institute of Central Computation and Knowledge. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made.

Portico

All published articles are preserved here permanently:

https://www.portico.org/publishers/icck/